iCex®

Analyze & Control Remotely

Fourth-generation SCADA system

Modern cloud-based SCADA

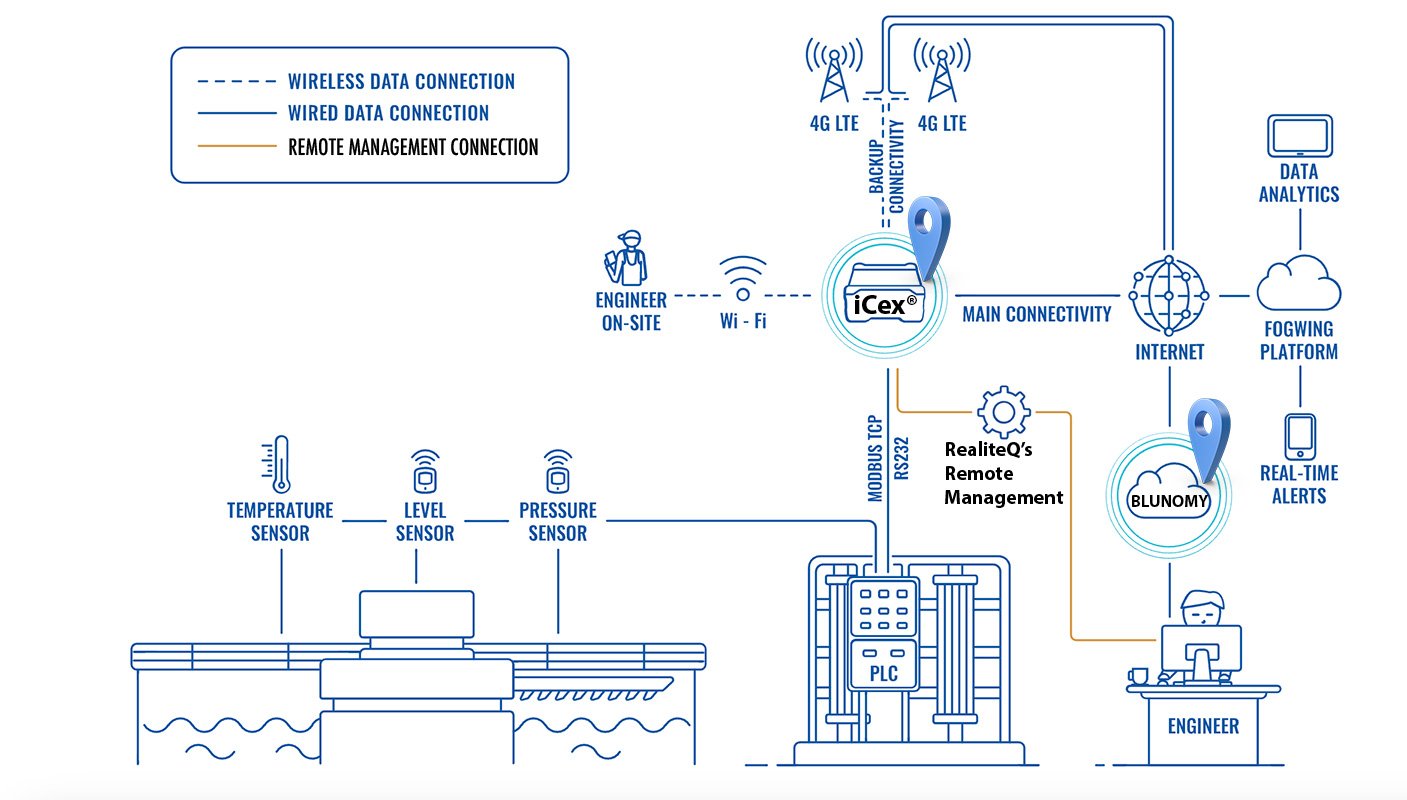

Blunomy powered by Israeli RealiteQ web (Cloud) SCADA solution, end-to-end (Telemetry, UI/HMI software & Service) Information and Communication Technology (ICT) that gathers and controls critical and operational data, in real time from sensors, analyzers and controllers/PLC.

Water & Waste Water

Automate the system of an entire Fresh water reservoir or wastewater treatment plant without changing existing equipment. Read More

Renewable Energy

iCEX connected to a sensor that tracks the nacelle mechanism’s vibration, magnetic field, and temperature has irreversibly changed how the mechanism is monitored and controlled remotely. Read More

Industrial

Global adoption of automation, AI and robotics as a mean to increase productivity is inseparable from the ability to monitor and manage equipment remotely.

Read More

iCex® is deployed in 40+ Countries

iCex® + Control Dashboard

Features

REAL-TIME ALERT SYSTEM

Use real-time email, Telegram and SMS alerts to stay informed on what’s happening with your devices. Special alerts can be configured for various events.

ACTIVITY REPORTS

Set up a custom reporting system that contains information on relevant device parameters. Generate reports periodically or whenever needed.

SECURITY

RealiteQ is used by thousands of businesses globally every day. All servers running are hosted by AWS and comply with CIS v7 infrastructure security certificate developed to align with the latest cyber threat data and reflect today’s current threat environment.

DEVICE MULTI-CONFIGURATION

Remotely set and use parameters for multiple devices with the flexibility to choose which changes will apply to which routers. There is a possibility to filter out by tags, location, model, etc.

CONSTANT UPDATES

Update hundreds of devices to the latest version in just a few clicks. Regular functionality and security improvements and entirely new features that come with the new device firmware.

REMOTELY ACCESS NON-REALITEQ DEVICES

Blunomy can generate remote access links and reach the equipment connected within the same network.

Case Study:

ENABLING CONTROL OVER A WASTEWATER TREATMENT PLANT

The monitoring and infrastructure’s control must be automated to eliminate human errors, but it must be realized without changing any existing equipment, as legacy industrial equipment often doesn’t support features like Wi-Fi or Bluetooth, and doesn’t even have Ethernet interfaces. So, it’s quite a tough challenge…

- All

- Agriculture

- Energy

- Industry & OEM

- Water & Waste Water

Background: RealiteQ was asked to provide a monitoring and operating solution for a relatively small corporation, which is only authorized…

Background: The agricultural company at Kibbutz Mizra in Israel has a large number of linear/pivot irrigation machines, distributed over extensive…

Background: A local distributor and integrator of GE control systems in Austria was looking for a real-time communications system that…

Background: In Cameroon, Africa, the base stations for its cellular network are partially fed by solar energy systems, particularly in…

Background: The German company TBS is a virtual provider of energy that connects various generators throughout Germany to local power…

Background: This pilot project is being carried out at American Water’s Innovation Department as part of the company’s strategy of…